New tool raises cutting productivity, allowing higher feed rates with less vibration

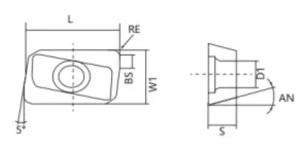

Kyoto/Neuss – Kyocera Unimerco Tooling GmbH introduced its new MFH - High Feed Milling Cutter, which features an anti-vibration design for increased productivity in ramping and helical milling at high speeds. The MFH offers a variety of cutting options with three different inserts designed specifically to enhance general milling; to support large depth-of-cut operations (up to 5mm), and to provide a wiper edge for roughing and finishing, even in small machining centers. Carbide Inserts TOGT

This state-of-the-art cutting tool offers a convex helical edge design to reduce cutting forces during initial workpiece contact. The MFH is ideal for a wide application range including face milling and shouldering, slotting, ramping, helical milling and plunging. The MFH is Kyocera’s first high-feed milling tool, and is being introduced in response to heavy market demand. It rounds out Kyocera’s comprehensive product line of cutting tools to meet diverse manufacturing challenges.

Inserts for the MFH come in new grades for difficult-to-cut materials, providing stability to help prevent insert fracturing and ensure high-efficiency machining.

The CA6535 insert is ideal for Ni-base heat-resistant alloys and martensitic stainless steel. It provides high heat- and wear-resistance with improved stability through the use of Kyocera’s thin-film CVD coating technology.

The PR1535 insert is ideal for titanium alloys an d precipitation-hardened stainless steel. Kyocera’s proprietary MEGACOAT NANO coating technology gives these inserts improved stability and longer tool life in milling applications.

The MFH Face Mill and Endmill both offer coolant holes for use in machining high-temperature alloys or improving surface roughness.

For more information, visit www.kyocera.eu.

Cnmg Insert Specification Source: Kyocera Unimerco Tooling GmbH